PNEUMATIC GREASE PUMPS

Pneumatic Lubricationpump. Buy online with 24/48 hour shipping.

A pneumatic Lubricationpump is a tool used for automated lubrication and greasing of equipment and machinery. Unlike manual Lubricationpumps that require manual operation, pneumatic Lubricationpumps work by supplying compressed air at a pressure of 4-8 bar that drives the lubricant through a system of pipes and nozzles.

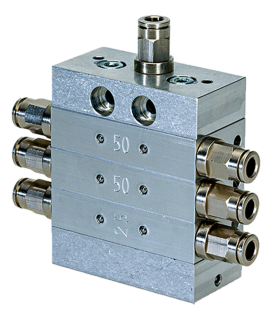

It is suitable for working with oils and greases up to NLGI 2. The pneumatic Lubricationpump consists of several key components, including a pumping mechanism, a Lubricationpump, a lubricant storage tank, control valves and a control unit.

The air motor drives the Lubricationpump, which sucks lubricant from the tank or reservoir and pushes it through pipes to the desired lubrication points. Control valves allow the amount and frequency of lubrication to be regulated, and the control unit can be programmed to set specific lubrication intervals or activated by sensors that detect the need for lubrication.

Pneumatic Lubricationpumps offer several advantages over manual lubrication methods. They automate the lubrication process, saving time and reducing the risk of human error. Additionally, they provide more precise and uniform lubrication, helping to extend equipment life and reduce maintenance costs. They also allow the lubrication of points that are difficult to access or dangerous for operators.

It is important to keep in mind that pneumatic Lubricationpumps require a compressor to obtain compressed air to operate and must be installed and maintained properly to guarantee their efficiency and durability. Additionally, it is necessary to use the correct type of lubricant according to the machine or equipment manufacturer's recommendations.

Other advantages of pneumatic Lubricationpumps are:

- Automation: The pneumatic Lubricationpump allows for continuous or scheduled lubrication of multiple Lubricationpoints without the need for constant manual intervention. This facilitates regular maintenance and proper lubrication of machinery.

- Flow Control: Electric Lubricationpumps usually have an adjustable flow control that allows you to regulate the amount of lubricant dispensed at each Lubricationpoint. This ensures precise and adequate lubrication of the components.

- Greater reach: By using a system of pipes and nozzles, electric Lubricationpumps can reach Lubricationpoints that are difficult to access manually. This is especially useful on complex or large machinery.

- Efficiency and time savings: The automated lubrication provided by electric Lubricationpumps allows for greater efficiency in the maintenance process, reducing the time and effort required compared to manual lubrication.

The sectors where pneumatic Lubricationpumps can be installed are those where a Lubricationsystem is needed. Practically the entire industry can apply this system.