PNEUMATIC DISTRIBUTORS

Subcategories

Pneumatic distributors. Buy tire distributors online.

Pneumatic distributors are mechanical devices that direct and regulate the movement of compressed air; They govern the exit and entry, closing or enabling, direction and flow of compressed air, in all its devices or peripherals. They are usually pneumatic cylinders

Types of pneumatic distributors

The types of pneumatic distributors could be selected from:

- Position or direction control distributor (distributors) These valves control the direction and diversion of air to the associated elements. Start and stop.

- Distributor or flow valve. Also called flow control valve. Their mission is to regulate the speed of the pneumatic cylinder, regulating the flow of compressed air.

- Distributor or pressure control valve. Its main function is to protect other elements of the electrical circuit from overpressures. Therefore, if they detect a high pressure in the circuit, reaching the maximum level, it will cut off the air flow. In this way, by cutting and opening the air flow, it is possible to constantly stabilize the pressure of the pneumatic circuit.

How pneumatic and parts distributors work

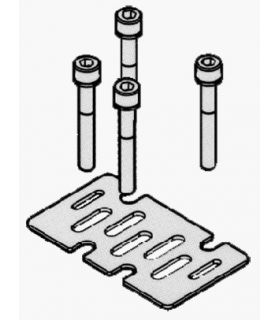

A distributor valve consists of two parts, completely differentiated. One would be the body, the so-called distributor, and the pilot or drive. The body consists of a casing or box, normally made of aluminum that houses a slider or clapet inside, which are responsible for distributing the compressed air from one path to another.

The piloting is the way we change the inner slide. There are several types:

- Pneumatic, through a compressed air signal, makes the slider or internal clapper move

- Electric. A coil with alternating or direct current causes a magnetic field and moves the internal slider or clapper.

- Manual, The movement of the slide or clapet is carried out manually

- Mechanics. Made by mechanical elements, such as pulleys, antennas, limit switches, stops, pivots, etc.

They are simple elements and easy to assemble. It requires little maintenance and is economical to install. Long durability, changing the gasket kit.

To identify each valve or distributor and the type of actuation, a universal symbology has been applied that determines it.

Pneumatic distributors are safe, do not have explosive characteristics or produce excessive heat. The compressed air used to move the pneumatic cylinders does not generate water hammer, which reduces breakdowns or damage to the equipment. They are used in practically all types of industries, where automation is present.