BLOW VALVES

Blow-off solenoid valves. Buy online with 24/48 hour shipping.

Blow valves and bag filters are components used in air filtration systems, such as industrial fume and dust collection systems.

The operation is as follows:

Blow-off valves: Also known as bag cleaning valves or pulse valves, they are devices used for the automatic cleaning of bag filters. These valves are designed to quickly release a jet of compressed air inside the filter sleeves, generating a pressure wave that dislodges the dust accumulated on their surface. This cleaning process is performed periodically to maintain the efficiency of the filtration system.

And bag filters are filtration systems used to capture solid particles suspended in the air, such as dust, smoke or ash. They consist of a series of sleeves or tubes of filter cloth arranged vertically in a structure. Contaminated air enters the system and passes through the sleeves, while particles are captured on the outer surface of the sleeves. Subsequently, the clean air is released into the environment. To maintain system efficiency, it is necessary to periodically clean the bags using the blow-off valves.

In summary, blow-off valves are devices used to clean bag filters in industrial air filtration systems. Together, these components help ensure efficient performance and good air quality in work environments.

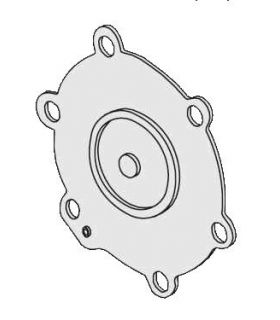

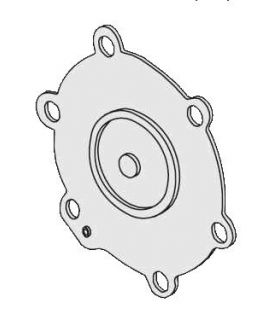

The bag filter solenoid valves are made of brass or aluminum and are controlled through either a pneumatic signal or an electrical signal through a coil at different voltages to choose from. The opening and closing is carried out by means of a membrane or diaphragm, which can be made of NBR or VITON.

There are many sizes and we have the option of selecting the valve with thread or with compression fitting. Its body with square holes allows a high flow rate, the springless construction, and the specially studied membrane device gives it the operating characteristics necessary for bag filter blowing installations.

A whole series of blowing solenoid valves can be controlled using a timer, which automates the activation time and period. These valves have the function of quickly injecting compressed air into the filters to loosen and eliminate accumulated dust, thus maintaining the efficiency of the filtration system.

Common applications of baghouse blow-off valves:

- Cement industry: In cement plants, large amounts of dust are generated during the production and material handling processes. Bag filter blow-off valves are used to keep dust collector filters clean, preventing clogging and ensuring efficient operation.

- Steel industry: In blast furnaces and other steel production areas, fumes and dust particles are generated that must be captured to maintain a safe work environment and comply with environmental regulations. Baghouse blow-off valves are essential for the proper functioning of the filtration systems used in these facilities.

- Chemical and pharmaceutical industry: In chemical and pharmaceutical processes, toxic or dangerous substances can be generated, as well as fine dusts that must be captured to avoid air pollution and protect the health of workers. Baghouse blow-off valves are used to keep filtration systems clean and ensure adequate air quality in these industries.

- Food Processing Industry: In food processing facilities, it is important to maintain a clean, contaminant-free environment to ensure the safety and quality of food products. Bag filter blow valves are used in filtration systems to remove dust particles and other contaminants that may affect food quality.