LUBRICUS LUB-V Automatic greasers

LUBRICUS V automatic graters. Buy online at the best price

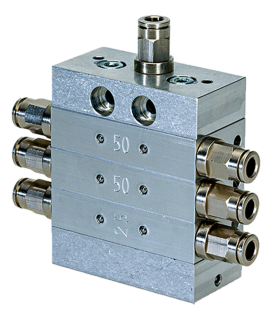

The Lubricus V automatic oiler is a device used to apply oil or Lubricationconstantly and uniformly to moving machinery, equipment and systems and operates using a voltage of 24V DC. This model can be supplied with 1 or 2 outlets for diameter 6 tube with quick-connect fittings included and can reliably supply lubricant to lubrication points for up to 36 months. Optionally it can be supplied with a 5 or 10 meter power cable, with straight or angled connector, with LED indicating when there is voltage. This Lubricus V is ideal for discontinuous services.

It has the feature of pause mode or boost mode operation. The Lubricus V system is innovative, flexible and variable! Lubricus V opens a new door in the world of automatic lubrication. Lubricus V allows lubricant to be supplied both to individual points and to a complete group of lubrication points of different types over a long period of time continuously and safely thanks to the placement of a progressive distributor. Thanks to its compact dimensions, Lubricus V is ideal for subsequent installation in different applications, allowing an individual lubrication solution ideal for almost any application.

The Lubricus V model, which operates with 24 V DC power, is used whenever a 24 VDC power supply is desired or necessary. The lubricant is drained automatically, optionally 1-36 months (or pause time).

They can operate with oils or greases up to an NLGI 2 consistency. Lubricus V automatic greasers are refillable once the oil or Lubricationis used up. There are 2 cartridge capacities for refilling, 400 ml and 250 ml. Being refillable, it can be loaded with any type of Lubricationor ordered directly with the factory pre-established grease. There is a Lubricationfor each type of application, universal greases, lithium greases, food greases, ecological greases, high temperature greases, for large loads, etc...

The working pressure is up to 70 bar (1015 psi) thanks to its internal electromechanical gear motor. The service temperature is from -20ºC to +70ºC The flow does not vary depending on the temperature, as can occur with gas-operated lubricators The programming of the Lubricus V lubrication unit is simple and intuitive using a digital panel with magnetic control. Fully programmable and adjustable to each need. All functions and alarms can be displayed on the LED panel.

It has the Quick-Check function that measures the back pressure in the circuit and compensates the flow to introduce the one that has been programmed and performs the additional work.

The fields of application of the Lubricus V automatic oiler are very wide, for example these would be some applications:

- Heavy Machinery: Automatic oilers are used on heavy machinery such as excavators, bulldozers, cranes and other construction equipment to lubricate critical components that are constantly moving.

- Transportation: Automatic oilers are also used in transportation vehicles, such as trucks, buses, and trains, to lubricate suspension components, transmission, and other systems.

- Industrial machinery: In industry, automatic greasers are used in machinery such as presses, lathes, milling machines, packaging equipment, among others, to lubricate critical components that are constantly moving.

- Agricultural Equipment: Automatic oilers are used on agricultural equipment, such as tractors, combines, planters, among others, to lubricate critical components that are constantly moving.

- Marine Equipment: Automatic oilers are used on ships and boats to lubricate critical components that are constantly moving, such as engines, propellers and pumps.