AUTOMATIC LUBRICATION ACCESSORIES

Automatic lubrication accessories are elements and devices that are used to automatically apply lubricant to different lubrication points of a machine or equipment. These accessories are very useful for maintaining constant and adequate lubrication of machinery, which reduces wear and extends the useful life of components.

Some of the most common automatic lubrication accessories are:

- Drip lubrication systems: These are systems that apply lubricant to the lubrication points through a constant drip. These systems can be adjustable to regulate the amount of lubricant supplied.

- Circulation lubrication systems: These are systems that recirculate lubricant through machinery to lubricate moving components. These systems may include pumps, filters, and valves to control the quantity and quality of the lubricant.

- Spray lubrication systems: These are systems that apply lubricant in the form of an aerosol or fine spray at the lubrication points. These systems can be useful for lubricating parts that are difficult to access or that require uniform application of the lubricant.

- Injection lubrication systems: These are systems that supply lubricant through an injection nozzle at the lubrication points. These systems can be adjustable to control the amount and frequency of lubrication.

- Centralized lubrication systems, also called progressive: It is a lubrication method used in industrial machinery to guarantee adequate and constant lubrication of moving parts. In a progressive lubrication system, a centralized lubrication pump supplies oil or Lubricationto a series of progressive valves. These valves are activated sequentially to deliver small amounts of lubricant to different lubrication points on the machinery, ensuring that each point receives the proper amount of lubrication. Progressive lubrication is used on machinery that has multiple lubrication points, which can be difficult to reach manually. This method ensures that each lubrication point receives the right amount of lubricant at the right time, helping to extend the life of the machinery and reduce the risk of errors.

All the elements of these systems that help automatic lubrication are:

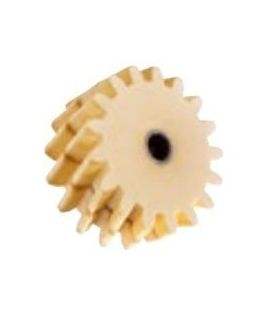

Brushes, sprayers, progressive distributors, desiccant filters, high-pressure fittings for oils and greases, single and double lubrication pinions, gear wheels for different modules, straight or left-hand, among others.

It is also worth mentioning all the oils and greases, which are the fluid that actually lubricates the machines or equipment. They generally tend to have a consistency of up to NLGI 2. If the Lubricationis thicker, they do not usually work at optimal performance.